January 18, 2023

When the topic of chemical recycling comes up at SPC events, it’s no surprise that the conversation typically focuses on how these technologies apply to plastic packaging. Part of the promise of chemical recycling, though, is the ability to recycle polymers in numerous forms such as in carpets, mattresses, durable plastics, and other items not well-suited for mechanical recycling. In the “Chemical Recycling Beyond Packaging,” session at SPC Advance 2022, Jodie Morgan, CEO of Nexus Circular, Holli Alexander, Strategic Initiatives Manager for Global Sustainability at Eastman, and Thomas Philipon, CEO of TotalEnergies Corbion, came together on stage to talk about the benefits of cross-sector collaboration in chemical recycling.

First… what is “chemical recycling”?

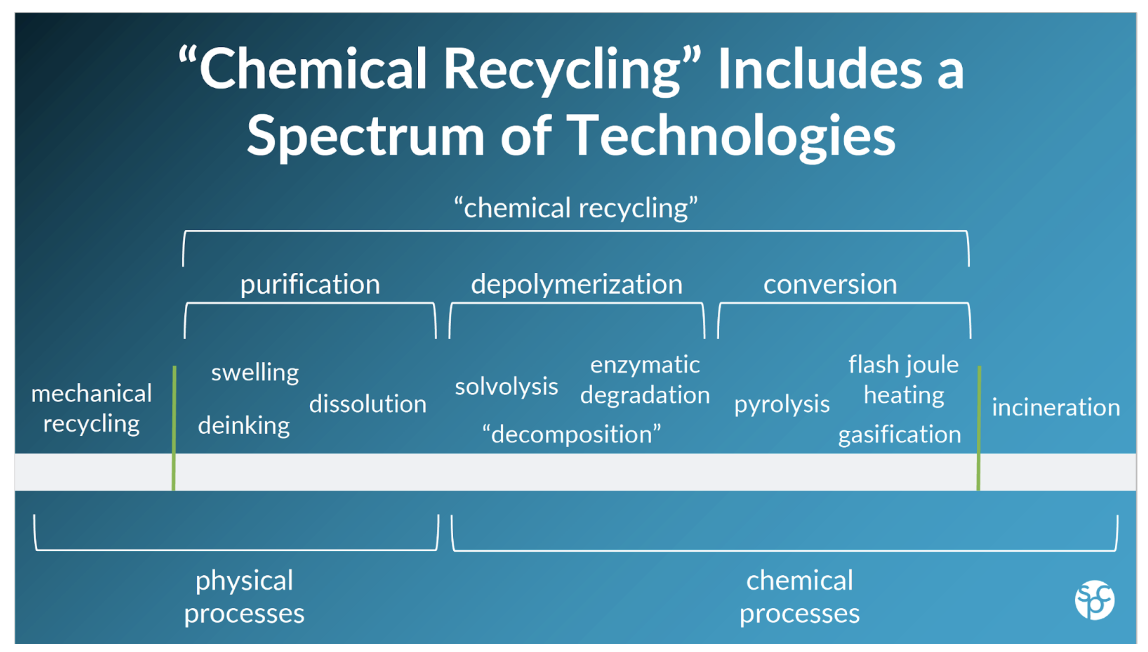

The session began by level-setting around the term “chemical recycling.” While each industry professional in the space likely has their own preferred term, we used the terms chemical recycling, advanced recycling, molecular recycling, and non-mechanical recycling interchangeably for this session. Importantly, when using any of these terms that include the word “recycling,” we are referring to processes where the outputs feed back into materials like plastics and not processes where the outputs are used as fuels.

Among chemical recycling technologies, there are three main categories: purification, depolymerization, and conversion. This session focused on depolymerization and conversion technologies, which are more likely to be used for moving material among different applications compared to purification technologies. Since purification technologies use physical processes that do not change the underlying polymer structure, the output material must be used in applications where the properties or specifications match those of the input material. In contrast, material from depolymerization and conversion can be used to construct new polymers with properties different from the inputs. Depolymerization technologies that produce monomers provide an opportunity to construct new polymers with different chain lengths (determining properties such as intrinsic viscosity and melt flow) and/or different combinations of monomers. The outputs from conversion are even more versatile in terms of what applications they can be used for, as the basic chemicals produced by these technologies can feed back into chemical manufacturing processes in a similar way to petrochemical feedstocks.

Polymers and processes

With the stage set, each panelist introduced their company’s chemical recycling process(es), shared what polymers their processes handle, and listed some applications aside from packaging that also use these polymers.

First, Morgan explained that Nexus Circular operates a commercial-scale pyrolysis facility in the Atlanta area that produces what they call “circular liquid.” The process takes polyethylene (PE), polypropylene (PP), and polystyrene (PS) feedstocks. Morgan named the automotive industry as another large user of these materials in addition to packaging.

Next, Alexander spoke about Eastman’s work in both the depolymerization and conversion spaces. Eastman currently operates a facility in Tennessee where polyethylene terephthalate (PET) is depolymerized via a glycolysis process and has recently built a facility to depolymerize PET via methanolysis. The monomers from these “polyester renewal” technologies are used to make new types of polyesters that can go into products such as reusable water bottles. Eastman’s “carbon renewal technology” is a gasification process that takes mixed plastics among other feedstocks to produce basic chemicals that are then used to make cellulosic plastics. These cellulosic plastics have been used in items such as eyeglass frames and textiles.

Last, Philipon shared that TotalEnergies Corbion (a 50/50 venture between TotalEnergies and Corbion) uses a hydrolysis process to depolymerize polylactic acid (PLA). TotalEnergies Corbion operates a facility in Thailand where lactide monomer is made into new PLA. Although PLA is produced and used on a smaller scale compared to other plastics in packaging, it has multiple other applications. Philipon mentioned 3D printing as another industry where PLA plays a role.

Ecosystem of plastics recycling

Although many challenges remain for plastic packaging to be collected, sorted and ultimately recycled, it’s miles ahead of other plastic products in that at least some plastic packaging fits into established curbside collection models. Still, taking lessons from other sectors is key to finding solutions for hard-to-recycle plastic packaging. Philipon described material recovery as an ecosystem—where many players have important roles, and players are highly interconnected and dependent on each other. Rather than pin the journey to plastic circularity on any one company, we have to collaborate and find ways to bolster the entire system. Alexander brought up the many items that are currently listed as “not accepted” in curbside recycling guidance and asked which of these items might be accepted curbside in the future. She acknowledged that we won’t be recycling everything overnight but encouraged aiming for acceptance of more items in curbside collection rather than fewer. Collaboration in this materials ecosystem also includes collaboration between chemical and mechanical recyclers to match materials with the right process. Morgan mentioned that items such as plastic containers for motor oil or paint are contaminants in mechanical recycling processes but can enter a pyrolysis process with no problem.

So how do we enable this collaborative, resilient plastic recycling ecosystem? Morgan shared that although chemical recyclers can take different materials or formats than mechanical recyclers, design for recycling is still critical. Chemical recycling is not a catch-all, but rather each company has its own specifications for the material streams it accepts. For instance, components other than PE and PP in multilayer packaging can cause issues for Nexus Circular’s process and need to be limited. Polyvinyl chloride (PVC) was called out as undesirable for all the technologies represented. Philipon identified mass balance accounting as a key enabler for building up the plastics recycling ecosystem. He emphasized that it’s imperative for recycled material accounting practices to be credible. Policy also came up in the discussion. Alexander told us that Eastman recycles carpet collected through California’s extended producer responsibility (EPR) scheme for carpets. Currently, this carpet is being sent to Tennessee for recycling, and Alexander highlighted the need for expanding the network of recycling options and localizing recycling efforts through more widespread EPR.

Outlook

The conversation closed by talking about what the future holds and what role we can expect chemical recycling to play. Morgan pointed out that the scale of plastic waste generation is outpacing the capacity and capabilities of mechanical recycling. Mechanical recycling can be expected to accommodate some of this growth, but we are going to need multiple approaches. In terms of the timeline for chemical recycling technologies to scale, Morgan estimated it will take 10-20 years for chemical recycling to be available at a level that begins to match the scale of plastic waste. Alexander brought up supply chain problems that have made scaling even more challenging. She stated that Eastman’s methanolysis plant took three years to build for this reason.

The panelists all shared the sentiment that further education around and understanding chemical recycling technologies are important for these solutions to be dispatched most effectively. Alexander added that we don’t know what emerging recycling technologies will be capable of in the future. She encouraged thinking about the spectrum of chemical recycling technologies based on principles—especially for policymaking, prioritizing reduction, then reuse, then recycling will be a better guide than attempting to make binary judgments on specific technologies. Philipon expressed that so much is still unknown but that we can start from what we know, and going forward we will have to learn by doing, by trialing and iterating ideas, to make chemical recycling and the entire recycling ecosystem work better.

The overarching theme in this session was that this is a space where no company (or even sector) can be successful by striking out alone. In such an interdependent economy, getting out of step with the rest of the system likely means being stranded without reliable feedstocks or reliable markets. Collaboration is absolutely crucial. Collection, sortation, and recycling innovations and infrastructure need to grow together, in sync, for the circular plastics ecosystem to thrive.

Want to know more about developments in the landscape of chemical recycling technologies? SPC members can continue learning about chemical recycling by viewing past resources or joining future meetings of the SPC Chemical Recycling Collaborative.