October 26, 2022

This annual award celebrates the people and organizations behind the biggest achievements in sustainably innovative packaging.

CHARLOTTESVILLE, VA — For over five years, the SPC Innovator Awards have featured companies’ dedication to continually improve sustainable packaging. The goal of these awards is to highlight novel solutions and inspire other organizations within the space to test and scale sustainable packaging innovations.

The Sustainable Packaging Coalition congratulated the winners of the 2022 SPC Innovator Awards on the first day of SPC Advance during an awards ceremony sponsored by Trayak. Upon taking the stage, the winners spoke to what stood out to them among the innovations this year: collaboration. Forming new partnerships, working with different parts of the supply chain, and investing in new technology all strengthened the winning innovations.

We are thrilled to announce the three 2022 SPC Innovator Award winners in Responsible Sourcing, Design Optimization, and Recovery innovation categories. Read more about what the winning companies are working on below.

Innovation in Responsible Sourcing Winner

Flöter Verpackungs-Service GmbH | AirWave PaperWave

Starting to develop this idea in 2018, Flöter Verpackungs-Service GmbH’s inflatable paper cushion solution actively works to replace plastic e-commerce cushions. The company made it a point to focus on compostability in addition to recyclability, recognizing that composting can be a global end-of-life scenario. Flöter Verpackungs-Service GmbH developed a solution using Forest Stewardship Council (FSC)-certified paper and a potato starch lining, designed to be both curbside recyclable and compostable. Their hope is to end their own plastic-based production and transition to air and paper-based materials in the near future.

Starting to develop this idea in 2018, Flöter Verpackungs-Service GmbH’s inflatable paper cushion solution actively works to replace plastic e-commerce cushions. The company made it a point to focus on compostability in addition to recyclability, recognizing that composting can be a global end-of-life scenario. Flöter Verpackungs-Service GmbH developed a solution using Forest Stewardship Council (FSC)-certified paper and a potato starch lining, designed to be both curbside recyclable and compostable. Their hope is to end their own plastic-based production and transition to air and paper-based materials in the near future.

The Importance: Because the air cushions are produced directly at the packing station, additional energy expenditure and CO2 emissions are saved during transport. PaperWave can be disposed of in both the organic waste or paper recycling bins. When disposing of it, the consumer is able to easily identify that it is paper, and the product also bears the RESY mark as well as the sorting symbol 22PAP, common symbols in the European market. In addition, the product has been certified by the Paper Technology Foundation in Munich (PTS) as recyclable.

Innovation in Design Optimization Winner

WestRock | KD-Fold™

During their acceptance speech, WestRock spoke to how they brought many parts of the supply chain together and worked closely with FedEx to endlessly trial and test their design for a winning solution. Outperforming a standard plastic mailer, the KD-Fold™ was recognized for its operational efficiencies. It effectively minimizes fiber material with a tight fit that avoids the use of void fill. This design not only improved efficiency but storage space on the shipping pallet as well.

During their acceptance speech, WestRock spoke to how they brought many parts of the supply chain together and worked closely with FedEx to endlessly trial and test their design for a winning solution. Outperforming a standard plastic mailer, the KD-Fold™ was recognized for its operational efficiencies. It effectively minimizes fiber material with a tight fit that avoids the use of void fill. This design not only improved efficiency but storage space on the shipping pallet as well.

The Importance: The KD-Fold™ uses an average of 50% less paper than a small, corrugated box needed for the same contents. KD-Fold™ is both Sustainable Forestry Initiative (SFI) and FSC certified. It is also curbside recyclable. The Pak On Demand™ mailer system produces custom, sustainable fiber-based mailers on demand and seals the package for shipment. This system has a footprint of only 5 feet by 12 feet, requiring less space in back-of-store operations or space used for e-commerce order fulfillment. Since only one operator is needed for the Pak On Demand™, labor reduction and savings are possible.

Innovation in Recovery Winner

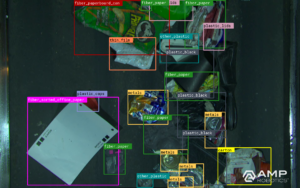

AMP Robotics | How AI and Producer Collaboration are Influencing Recovery and Driving Increased Recycling Rates

AMP Robotics’s winning innovation turned to the potential of Artificial Intelligence (AI) to successfully sort through the messiest of recycling streams. In partnership with Sonoco, a global packaging provider, AMP Robotics created a new material category within its neural network specific to rigid paperboard cans—items like Pringles cans and coffee, nut, and snack containers. The partnership drives increased recycling rates for spiral-wound paper canisters with steel and paper bottoms produced by Sonoco and other manufacturers. In addition to being a manufacturer, Sonoco is a recycler, operating more than 40 recycling facilities globally. The company has deployed an AMP Cortex™ intelligent robotics system in one of its facilities, with a second planned in another; this recycling relationship enables Sonoco to directly test and leverage AMP’s technology.

AMP Robotics’s winning innovation turned to the potential of Artificial Intelligence (AI) to successfully sort through the messiest of recycling streams. In partnership with Sonoco, a global packaging provider, AMP Robotics created a new material category within its neural network specific to rigid paperboard cans—items like Pringles cans and coffee, nut, and snack containers. The partnership drives increased recycling rates for spiral-wound paper canisters with steel and paper bottoms produced by Sonoco and other manufacturers. In addition to being a manufacturer, Sonoco is a recycler, operating more than 40 recycling facilities globally. The company has deployed an AMP Cortex™ intelligent robotics system in one of its facilities, with a second planned in another; this recycling relationship enables Sonoco to directly test and leverage AMP’s technology.

The Importance: AMP is working with companies across the spectrum of recyclable materials to adapt its AI platform to the specificity of a manufacturer or brand and disperse the sorting capability to materials recovery facilities (MRFs) with its robotic sorting systems. After beginning testing in 2021, their AI is now able to successfully identify and sort 50 billion packaging types and will only improve with more technological advancements. With more and more companies setting PCR commitments, AMP Robotics went through an iterative series of real-world MRF trials to recover more and more materials from the waste stream. Any MRF with an AMP Cortex system can now accurately and efficiently sort Sonoco’s paper can to the desired stream. This enables manufacturers to directly influence what’s recoverable and take advantage of the ability to capture more of their specific packaging.

A big thank you to the multitude of companies who submitted their ideas and current work in the sustainable packaging space. The twelve 2022 finalists can be found in our archive library at the bottom of the page here. This archive dates back to submissions from 2017 if you find yourself curious about just how far the ideas in the past five years have come.

Beginning as the Trashies in 2015, and transitioning to the SPC Innovator Awards in 2017, we are continuing to evolve the SPC Innovator Awards to accelerate sustainable packaging designs and recovery systems. Stay tuned for more information about the next round of the awards on our website.